Creating new value that goes beyond parts repair and overhaul

Business Information

Special Overlay Welding and Surface Treatment

It is possible to repair nitrided and hard chrome-plated screws with overlay welding. We select welding materials such as Stellite and Colmonoy according to the type and purpose of the screw or barrel. This method improves resistance to corrosion, wear, and heat, leading to longer equipment life.

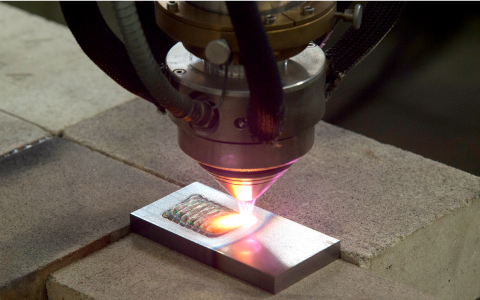

Cutting-Edge "Laser Cladding" Technology

We research and develop the new overlay welding technology, "laser cladding," which uses semiconductor lasers. The Nagoya Factory has a laboratory and performs laser cladding tests for performance improvement and long life.

We propose optimal maintenance and overhauls to our customers through software analysis of hydrostatic stress.

Integrated Overhaul System

Our Nagoya, China, and Thailand factories have an integrated system for overhaul. The system for kneading machines, rotary feeders, and related machines includes disassembly, repair of parts by overlay welding, processing of new parts, restoration, and reassembly. We offer not only maintenance services, but also proposals for performance improvement and long life based on data analysis.

-

MAINTENANCE TECHNICAL CENTER

Mother Factory for Maintenance Service in charge of the foundation of Welding Technique

-

YANTAI FRONTIER SPIRITS SHINWA

MAINTENANCE TECHNOLOGY CO.,LTD.Available to meet the needs for corrosion and abrasion resistance with special weld overlay, difficult-to-cut processing, and precise machining technology

-

SHINWA INTEC Co., Ltd.

The core of maintenance services in Southeast Asia is based in the suburbs of Bangkok.

High-Performance, Quality Products

We satisfy customer needs with new, high-functioning, quality processed products, such as screws and barrels made using the welding and thermal spraying technologies cultivated in our maintenance business. We offer a wide range of materials for corrosion resistance, heat, and wear, including cobalt, nickel, and ceramic, to enable the processing and manufacture of various products.

Example of owned equipment

-

Screw Processing

-

Nc Screw Cutting Machine

-

Machining Center

-

Wire-cut