Power for achieving the dream of next-generation technology

The micro-application process is an essential part of the manufacturing process for semiconductors, which are the core of AI, IoT, CASE, blockchain, and other fields where 5G technologies will change life and society. In recent years, in conjunction with improved functionality and performance in the field of semiconductor electronics, there is demand for even finer and more precise coating. As one of the world’s leading dispenser manufacturers, the Mechatronics System Center continues to pursue micro-volume, high-speed, and high-precision applications, which are expected to grow even further in the future, based on the keywords of “ultra-precision micro-dispensing application.”

The next standard

Shinwa offers the best underfill dispensing quality in the advance Semiconductor packaging and SMT assembly

SERIES LINE UP

Shinwa personnel can help you select a suitable system for your application needs

-

MsL

Ultra-High Precision dispenser

- Auger Screw Pump, Jet Pump

- Linear Servo Drive Gantry System(±5μm)

- Vision System & Height Sensor

- Calibration Systems to the certain parts of Shinwa

Ex.) Needle calibration, camera calibration

-

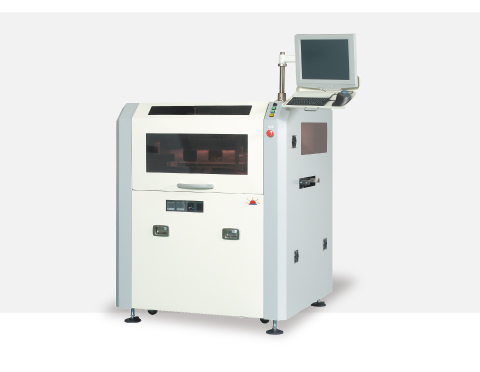

MsB

High Precision Dispenser

- Auger Screw Pump, Jet Pump

- Ball Screw Drive Gantry System(±10μm)

- Vision System & Height sensor

- Calibration Systems to the certain parts of Shinwa

Ex.)Needle calibration, camera calibration etc

-

Ss

Ultra-High Precision Dispenser

- Auger Screw Pump, Jet Pump

- Linear Serve Drive Gantry System(±5um)

- Vision System & Height sensor

- Calibration Systems to the certain parts of Shinwa

- Space Saving Small Foot Print (Foot print : 800mm×800mm)

- Applicable for small size substrate (Max : 150×150, Min : 30×50)

-

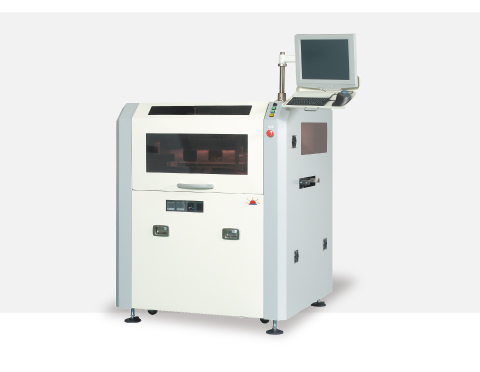

GP-2

Precision Dispenser

- Auger Screw Pump, Jet Pump

- Ball Screw Drive Gantry System(±15um)

- Vision System & Height sensor

- Calibration Systems to the certain parts of Shinwa

Ex.)Needle calibration, Camera calibration etc

PICK UP

Class 100 machine for the high

level clean environment.

level clean environment.

-

China Sales Company

SHINWA TIANJIN FACTORY AUTOMATION SYSTEM CENTER SUZHOU OFFICE

Room1301, Daogu International Center, No.500 Shuixiu Street, Wujiang, Suzhou